How to Install a Water Temp Gauge

By Rob Robinette

Why do you need to add a water temp gauge when the 3rd gen RX-7 comes with one?

Because the stock gauge won't show a rise in water temp until it's very, very hot and too late.

Mike Putnam wrote:

While working on the temperature gauge linearization I came to the realization that the H mark on the standard third gen temperature gauge indicates 266 deg F. The coolant recall replaced the original 1.3 Bar radiator cap with a 0.9 Bar cap. A 50% antifreeze mixture at 0.9 bar pressure boils at approximately 261 deg F. So the H mark on your standard stock temperature gauge really tells you at what point you have converted your gasoline engine into a steam engine. One more reason to modify your temperature gauge.

The first thing to decide is what type of gauge to install. I went with the Cyberdyne digital gauge because it's electric. It is much easier to run a single wire through the firewall than trying to get a mechanical gauge's probe and probe cable through. The Cyberdyne gauge also has a small, easy to install 1/8th inch NPT (National Pipe Thread) temperature probe and +- 2 degree accuracy. I purchased it from http://www.jegs.com. You'll need the gauge ($30) and a wire kit (temp probe & wire $10). Both are available from Jeg's and http://www.summitracing.com. You'll also need a 1/8th inch NPT tap to tap the temperature probe hole.

More info on installing gauges can be found in the gauge installation how-to.

AutoMeter mechanical analog water temp gauge and huge temp probe and cable (the cable and probe do not detach from the gauge for installation!)

If you don't want to drill into your thermostat housing to install the temperature probe, you can install the probe into the throttle body coolant lines by splicing in a 1/8th inch NPT "T". Any hardware store that carries plumbing supplies will have the NPT "T" (Home Depot & Lowe's too). Just take your probe or gauge into the store and find the "T" that fits. The Cyberdyne probe will go into one hole, and insert two 3/8" hose adapters into the two other holes. You'll need to ground the "T" so the electric probe will work. A mechanical probe doesn't need to be grounded. The AutoMeter mechanical temp probe is so big you would need a much bigger "T". Remember to use Teflon tape or pipe thread compound to seal the threads on NPT fittings, but make sure at least some of the temperature probe's threads contact bare metal for proper electrical grounding.

Hole for the temp probe (my radiator cap neck is a 2nd gen part used to eliminate the AST) Chuck Westbrook Adds: A better place to put the sending unit is to the right, behind the letters "OL" in HOLE (red dot). That places it directly in front of the thermostat and more out of the way.

To tap into the thermostat housing you'll need to remove the intercooler.

Remove the large coolant hose's (runs from the bottom of the thermostat housing to the radiator) upper connection. You'll lose about 1 quart of coolant. This will keep the drill and tap debris out of the cooling system. Put some rags or paper towels below the hole and over the open hose to catch the aluminum bits during the drilling. Try not to ram the drill bit too far into the thermostat housing when you break through. Next lubricate and tap the hole. Periodically test the fit of the temp probe. You want the probe to go almost all the way into the hole when tight. Flush out the thermostat housing with water when finished tapping and before inserting the probe for the last time.

Using 1/8th inch NPT tap

I covered half the probe's threads with Teflon tape to help it seal. An electric probe must have some metal-to-metal contact for electrical ground. Don't over-tighten the probe. It's pretty easy to strip aluminum.

Run the probe's wire through the firewall to your gauge. You can use the same route as the battery cable (battery relocated to the bin). I used the hole I drilled when I installed my shift light (see photo below).

The Cyberdyne gauge needs switched power, a ground and the probe connection to function. The probe is a thermistor (variable resistor) that changes it's resistance with heat (more heat less resistance). The gauge is really just an Ohm meter calibrated to degrees. Good luck.

Temperature probe installed

You can compare the accuracy of your gauge to the ECU's water temp sensor by checking when the cooling fans come on. Let the car idle until the fan comes on. The ECU turns the fans on (low speed) at 220 degrees F. It should go to high speed at 226.

Where I went through the fire wall

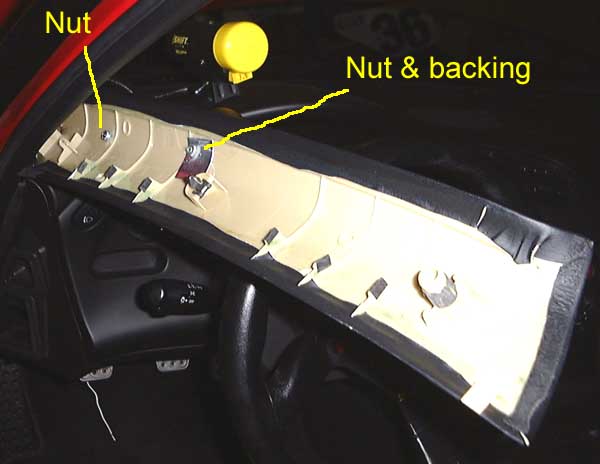

Back side of the AutoMeter A-pillar dual gauge pod

With A-pillar trim removed, hole in dash is exposed to run wiring

The installed pod, boost gauge and Cyberdyne digital water temp gauge

If you don't use a pod you can mount individual gauge cups to the A-pillar, notice the aluminum sheet used to reinforce the plastic A-pillar (used for large 2 5/8 inch gauge). Other gauge mounting options can be found at the gauge installation how-to.

What Temperatures to Look For

From page T-24, Mazda Service Highlights:

Normal operating temperature is 158 - 221 deg F

My Cyberdyne digital showed 231 degrees when the low speed fan came on (ECU turns it on at 220) and went to 240 degrees during idle before the fans cooled it down. It ran at a constant 175 degrees just tooling around (55 degrees F outside) and rose to a high of 194 during spirited street driving.

Rob Robinette